Manufacturing Technology

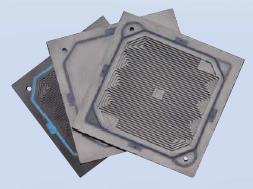

We apply low-cost molding processes for serial production of bipolar plates as well as CNC machining for manufaturing of prototype plates.

Experienced in-house tool shop uses the most advanced equipment for mold manufacturing.

We offer support to promote designs that are highly compatible with our molding process and our modular mold technology.

|

Further Advantages of Bipolar Plates

Product quality has been proven over the years for a wide range of fuel cell applications.

Plates have an excellent electrical and thermal conductivity (as rated by our customers).

|

Special hydrophilic or hydrophobic surface modifications

Improve the operational characteristics of bipolar plates without influencing their favorable electrical properties.

Hydrophilic surface

Hydrophobic surface

|